VI-20 EVOH barrier technology provides superior protection against diffusion of chemicals when compared to typical HDPE geomembranes. VI-20 is a layer of EVOH between two layers of polyethylene and is a copolymer of polyethylene (extrudes easily and improves bonding) and polyvinyl alcohol and ethylene vinyl alcohol (provides gas barrier).

It's your ideal partner for VOC control.

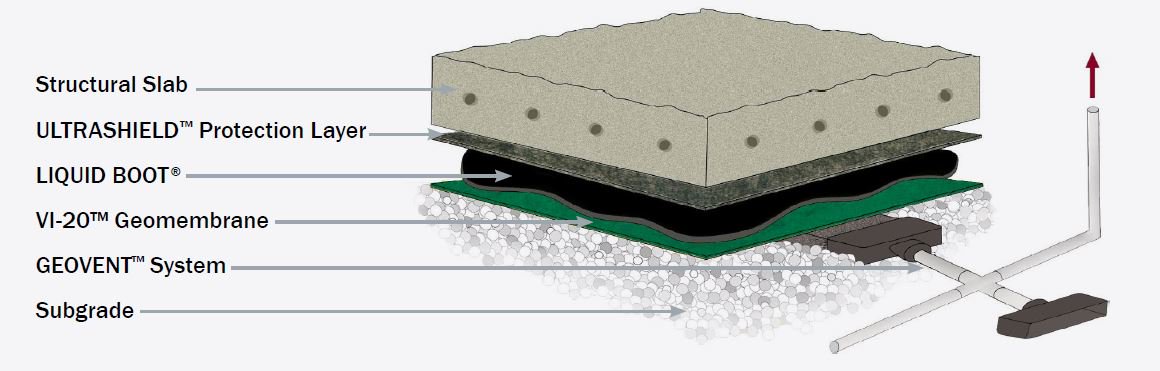

VI-20 geomembrane is a 7-layer co-extruded EVOH geomembrane made using high quality virgin-grade polyethylene and barrier resins to provide unmatched impact strength as well as superior resistance to VOC vapor transmission. EVOH technology has been shown to have VOC diffusion coefficients 20 times lower than an 80 mil HDPE geomembrane and serves as a highly resilient underslab and vertical wall barrier designed to restrict methane, radon and other harmful chemicals.

EVOH is a copolymer of polyethylene (extrudes easily and improves bonding) and polyvinyl alcohol and ethylene vinyl alcohol (provides gas barrier). Applications for EVOH originated in the manufacturing of automotive fuel systems to control emissions of hydrocarbons, whose use was mandated by the U.S. EPA and the CA Air Resources Board (CARB) to reduce VOC emissions.

| Properties | Rolls |

| Size | 10 ft x 150 ft unrolled panel size |

| Thickness | 20 mils (0.51 mm) |

| Weight | 160 lbs |

| Roll Diameter/Width | 11 in / 5 ft |

| Roll Core | 3 in |

| Color | Green |

Typical uses for VI-20 include installation under slab and on below grade vertical walls as a vapor barrier to minimize vapor and nuisance water (non-hydrostatic conditions) migration into buildings. It is also ideal for application with chlorinated solvents, BTEX, and other PAHs.